QUALITY

COMMITMENT TO QUALITY

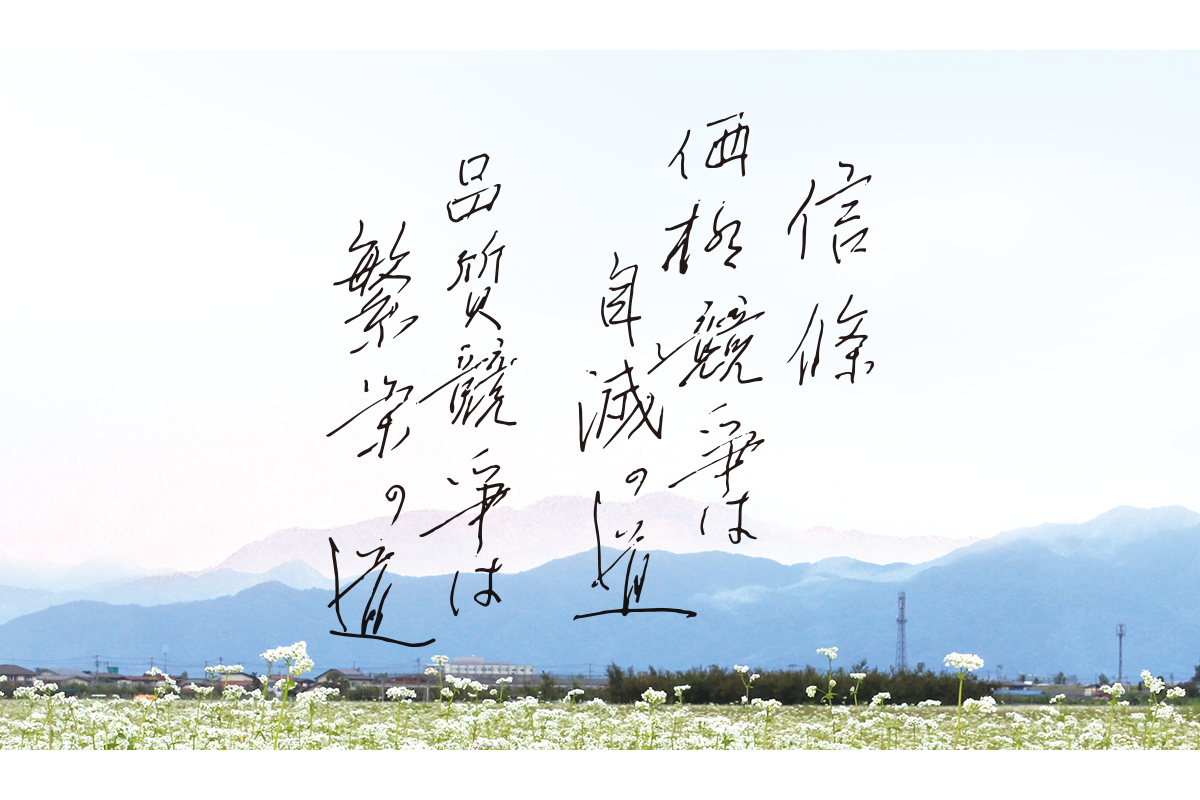

BUILDING A TRUSTING RELATIONSHIP WITH CUSTOMERS THROUGH QUALITY COMPETITION

Price wars are the path to self-destruction. Quality competition is the path to prosperity.

During the second generation of Ogawa, Masajiro Ogawa initiated this philosophy and we have upheld and valued it. Our mission is to consistently deliver products of high quality through ongoing research. We have built a quality control system that ensures safety across the board, from obtaining raw materials through distributing noodle products.

THE SIGNIFICANCE OF THE OGAWA BLENDING RECIPE

Applying the OGAWA 130 year old blending technique to maximize characteristics of Soba flour

The attributes of buckwheat vary by both by strain and origin. For example, “KITAWASE” from Hokkaido has the characteristics of a black hue and rich aroma. “MOGAMIWASE” from Yamagata has features of sweetness and richness. Even though the production origin is Yamagata, the soba variety “DEWAKAORI” is white in color and has a sweet flavor. Even if soba is of the same strain and grown in the same locale, its character differs based upon the cultivator. We optimize the proportion of soba flour depending upon season and product, maximize the taste of the ingredients and deliver stable quality of product to customers.

Developing unique noodle manufacturing techniques that use the minimum amount of salt

Salt is an important ingredient in Soba because it enhances gluten formation and moisturizes the surface of noodles during the drying process. However, it impairs the Soba aroma. We have cultivated authentic techniques that use the minimum amount of salt possible, one-tenth of standard Soba noodles. This allows consumers to enjoy optimal Soba aroma and flavor. In addition, the “SOBAYU” produced is incomparably delicious.

Blending varieties of wheat flour from around the world

Wheat flour is one of the more important ingredients used in all OGAWA noodle products. We have selected flour from Japan, the United States, Canada and Australia. The wheat flour must be low ash content and of the first grade. We optimize the proportion of flour depending upon season and product. Wheat flour gives OGAWA noodles their smooth, chewy and tender texture.

ARTISANSHIP AND STATE-OF-THE ART FACILITIES

The best noodle manufacturing environment even during harsh winters

Our facility creates the perfect conditions for noodle production. OGAWA’s soba and wheat noodle drying processes stretch for 1 km and noodles are dried slowly over a whole day and night. Controlling humidity and temperature is the most important aspect of this process, especially during the harsh winters of Yamagata. The drying process is designed to be airtight and has a three-layer structure and humidity and temperature are kept at optimal levels for noodle manufacturing.

Requirements for artisans to produce the tastiness of the most delicious noodles

Manufacturing the best quality noodles requires state-of-the-art facilities, but this is only in addition to the experienced techniques of skilled craftsmen. We do not rely solely upon automated processes; much of our quality control is done by hand. We do not produce soba noodles during the summer or the rainy season because at those times of year we cannot provide consistent quality of product. Business efficiency to the detriment of our noodles is not acceptable at OGAWA. We prioritize providing a reliable quality of products to meet our customers needs. This is our business stance. We keep to the traditional noodle recipe within a modern factory framework and do our best to supply only quality noodles.